So today I'm presenting the next stage of my process but the first stage of the actual judging. I do find this step to be a bit tedious but it's so very important! The Handcrafter's Spin Off is intended to represent sending your best alpaca fiber to handspinners for a premium price. Imagine that I, as a handspinner, has requested a 2 ounce sample of your alpaca. I am looking for a source for alpaca fiber and I know that I'll pay premium price for the best. How will the breeder/shepherd respond to my request? Will they grab the first handful or two on the top of whatever bag of fleece and jam it into a bag? Or will they skirt out the finest fiber from the better fleeces, prepare it carefully and present it to me like the premier fiber it is reported to be? This first part of the scoring is all about that presentation and quality. The way this contest is judged, a fiber seller could well use the scores to advertise to spinners the quality of their services and product. I know of one breeder who scored exceptionally well and sold the judged fleece for over $500!!! directly because of the scorecard. You can easily imagine the effect on the stud's breeding schedule.

Note: Unless otherwise noted, I have not chosen the photos because of their quality. I'm simply showing a random example. I've also blanked out entry numbers for the sake of privacy.

The first Judging criteria is First Impression. I look at the packaged sample before ever touching it. Is it presented well? Was time and care taken in selecting and preparing the sample? Is the fiber in good condition; not dirty, matted or messy? Can I easily sort the fiber for spinning? This is one step that can make or break a contest. ALL fiber can be presented well or poorly and that is the FIRST impression you make to your buyer! Mediocre fiber will sell for more if it is presented well and outstanding fiber will sell for less if you look like you couldn't care less how you treat your customer. There is simply no excuse for jamming a random sample in a bag and expecting people to pay top dollar.

The first Judging criteria is First Impression. I look at the packaged sample before ever touching it. Is it presented well? Was time and care taken in selecting and preparing the sample? Is the fiber in good condition; not dirty, matted or messy? Can I easily sort the fiber for spinning? This is one step that can make or break a contest. ALL fiber can be presented well or poorly and that is the FIRST impression you make to your buyer! Mediocre fiber will sell for more if it is presented well and outstanding fiber will sell for less if you look like you couldn't care less how you treat your customer. There is simply no excuse for jamming a random sample in a bag and expecting people to pay top dollar. An important observation at this point is looking for parasites. If ANY infestation is found, the sample is placed in the freezer for a few days. If I suspect the infestation is active and poses any threat to my own home and fiber stash, I remove that sample from my home and double bag it. You send any spinner a sample with parasites in it and you won't only lose their business, they will make sure that all their friends know not to buy from you! Spinners will not sacrifice or risk their own precious fiber collection no matter how good your alpaca is.

Every sample is weighed. Was the correct amount of fiber sent? If you sent less, did you overcharge me? If more, did you charge me for more than I asked?

Every sample is weighed. Was the correct amount of fiber sent? If you sent less, did you overcharge me? If more, did you charge me for more than I asked?  Points are also given for staple length with a minimum of 3 inches required. 5-7 locks are chosen from all over the sample. There are no extra points for a particular length of staple, but are the lengths CONSISTENT? It's rare to find all staples exactly the same but they should be very, very close. Points are deducted based on percentage of difference. a 1 inch difference between 3 and 4 inches is much more severe than between 11 and 12 inches. A very important evaluation is for fiber that is sound and has no tender breaks or weak tips. Either of these things can ruin an entire fleece by creating noils and pills in the resulting yarn.

Points are also given for staple length with a minimum of 3 inches required. 5-7 locks are chosen from all over the sample. There are no extra points for a particular length of staple, but are the lengths CONSISTENT? It's rare to find all staples exactly the same but they should be very, very close. Points are deducted based on percentage of difference. a 1 inch difference between 3 and 4 inches is much more severe than between 11 and 12 inches. A very important evaluation is for fiber that is sound and has no tender breaks or weak tips. Either of these things can ruin an entire fleece by creating noils and pills in the resulting yarn. Cleanliness is also very important and allocated 10 points. Now, washing the fiber is absolutely prohibited but there are things a fiber provider can do to minimize dirt. Separating, blowing, stroking and picking out short cuts is all expected. If this is done then the only dirt left will be some dust within the staple structure itself. How do you reduce that? Do not use overhead feeders to keep hay and chaff (this is VM = Vegetative Matter) out of the fleece. Keep pastures green and clean of bushes and trees that shed seed pods. Use hay that does not include seed heads!!!! Keep animals out of pastures that include mud and clay if at all possible. I have actually seen fleeces where the tips were clogged with what appears to be TAR. Whatever?!

Cleanliness is important because ideally, alpaca should be able to be spun without washing first. That will be more clear as I show you the next step of the judging in a few days.

Another criteria is Lack of second cuts. Second cuts happen when the blade goes back over the same area more than once. I have noticed that as the popularity of using Fiscar shears to do the shearing themselves, the incidence of severe second cuts has increased dramatically. The worst of these is mid staple cuts. Let's say you have fiber with a 5 inch staple. If you cut it down the middle, you know have 2 staples of 2.5 inches and that is 100% wasted fiber. At best you have very inconsistent staple length which no spinner wants.

Next is judging the fiber itself. Lack of medullated fibers, lock structure, Uniformity, Fineness, Hand, Luster. These are all traits that have everything to do with the genetics of the animal and less to do with husbandry.

Some specific notes:

Lack of medulatted fiber - these are the especially coarse fibers usually in the center of the lock of fiber. These fiber tend to stick out of the yarn like barbs on a wire fence.

Lock structure - Fleeces that are more dense will tend to keep staples distinct and separate. Locks that are open and loose will be prone to cotting and matting at the base near the skin. This cotting makes the fiber miserable for a spinner to process. On the other hand, a lock that is very tightly twisted together is also very difficult to open up without breaking the strands and creating noils and pills in the yarn.

Uniformity - this includes Lock and Fiber style, color, texture, crimp (huacaya only) and color. If a sample has much variety in any of these features it will diminish the quality of the resulting yarn.

Fineness - slightly obvious. Finer fiber is generally softer.

Hand - even fine fiber can be dry, brittle and fragile. Alpaca should be very soft and Suri should be distinctly silky. Healthy fiber should feel robust and stable.

Luster - I choose to break this scoring into two parts, one before spinning and one after the yarn is complete and washed. The presence of dust (alpacas are dust bathers) can hide the luster that is still present. The luster on the animal is important but the end result is even more important. I try very hard to balance that.

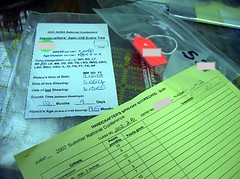

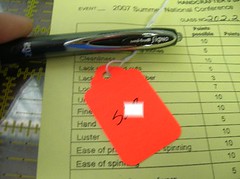

So now I check that all the information is correct, that the cards are filled out and legible.

I add a tag to the package because that is how I identify the skein after it's spun. Incidentally, I learned something about the pens I use. I was just looking for a pen that was resistant to running and bleeding if it gets wet. What I found was that this particular pen is designed to be resistant to solvents. According to the packaging, a current method of fraud is 'washing' checks to remove the written dollar amount and fill in a fraudulent amount. Wow, and I thought that just using ink was enough. Apparently not.

If there was something particularly notable about a sample, such as the presence of kemp fiber, mid-staple cuts, infestation, tender breaks...I will attach a sample and perhaps a brief explanation to the back of the score card. I go on the assumption that the breeder wants to learn about their fiber and would welcome an explanation. I also sometimes will include positive info on the back especially if it's unrelated to the judging. Perhaps something amusing about the sample (certain lock types give me the giggles they are so cute) or a color that really strikes me aesthetically. It's not taken into account in the scoring, but it might mean something to the breeder.

Now the sample locks and tag are placed in the marked small baggie and set aside with the corresponding score card in a small bin for that class. I process ALL the breed (Suri or Huacaya) samples before moving onto the next step of judging. This gives me the chance to forget any prejudices I might have about one sample or another. Trust me; after this process on 100 samples, I do NOT remember that one really awesome fawn sample. I'm lucky to remember my NAME.

So today, onto the next step of the process; combing and spinning the samples into a yarn. Until next time....

1 comment:

Thank you so much for all this information. This is very interesting!

Post a Comment